WE CREATED INTRIPLEX

SO WE COULD TELL SUCCESS

STORIES

WE CREATED INTRIPLEX

SO WE COULD TELL SUCCESS

STORIES

We are creative to our core

THE HOME OF METAL STAMPING INNOVATION

We’re a team of strategists, engineers, tool designers, product managers, and trailblazers. We are intensely curious, have years of manufacturing experience, and are committed to excellence and partnering with our customers.

Creativity is accelerated through a combination of imagination, ability, space, tools, interdisciplinary research, and materials. It is enhanced by having a place where ideas can be tested, refined, and tested again as rapidly as possible.

We lead the way in metal stamping innovation. From its inception in 2010, the Innovation Center has been an open space where engineers have access to labs, state-of-the-art prototyping, testing, and analysis tools, equipment, material, and hands-on, dedicated staff. You are invited to visit us, work from our offices, and test out your ideas. Through partnerships with our customers, the Innovation Center is an environment where concepts become solutions to your problems, where new discoveries are made, and relationships forged.

why we are here

Driven to make a difference

Innovation is at the heart of our enterprise. Since 1987, IntriPlex has pushed the envelope of precision forming technology with products that have changed industries and lead the way for others to follow. IntriPlex products solve complex problems and perform as promised, time and time again. We remain a worldwide leader in precision forming technology and are committed to collaborating closely with our customers to solve their toughest technical challenges.

The Innovation Center has a relentless focus on solving challenges, consistently manufacturing products to the most exacting of tolerances, and building trust.

Our Process

Advancement through collaboration

customer engagement putting people at the heart of innovation

Many companies interpret potential innovations from a business or marketing perspective, but we are always people focused. We are ultimately interested in understanding what our customers challenges are to provide design solutions. We engage with you directly and you’ll get feedback quickly. We like to think of ourselves as an extension to your team, your strategic partner.

Design & Strategy Development imagination elevating engineering

The continuing story of innovation at IntriPlex begins with the discipline of design and the understanding of engineering focused on delivering products that deliver solutions for the increasing expectations of the end-consumer.

Our Innovation Center is a hub for ideation and prototyping. Our customers can hash out ideas in meeting and open work spaces and build prototypes with us in the lab. We offer a full array of value-added design engineering and product development services, including research & development, design for manufacturing and rapid 3D prototyping.

Our Innovation Center is fully staffed with a potent mix of highly experienced engineers who work closely with you from concept through completion.

It’s our job to ensure that the final design can be manufactured efficiently, cost-effectively, and repeatably.

prototyping from concept to creation, it’s faster than you’d think

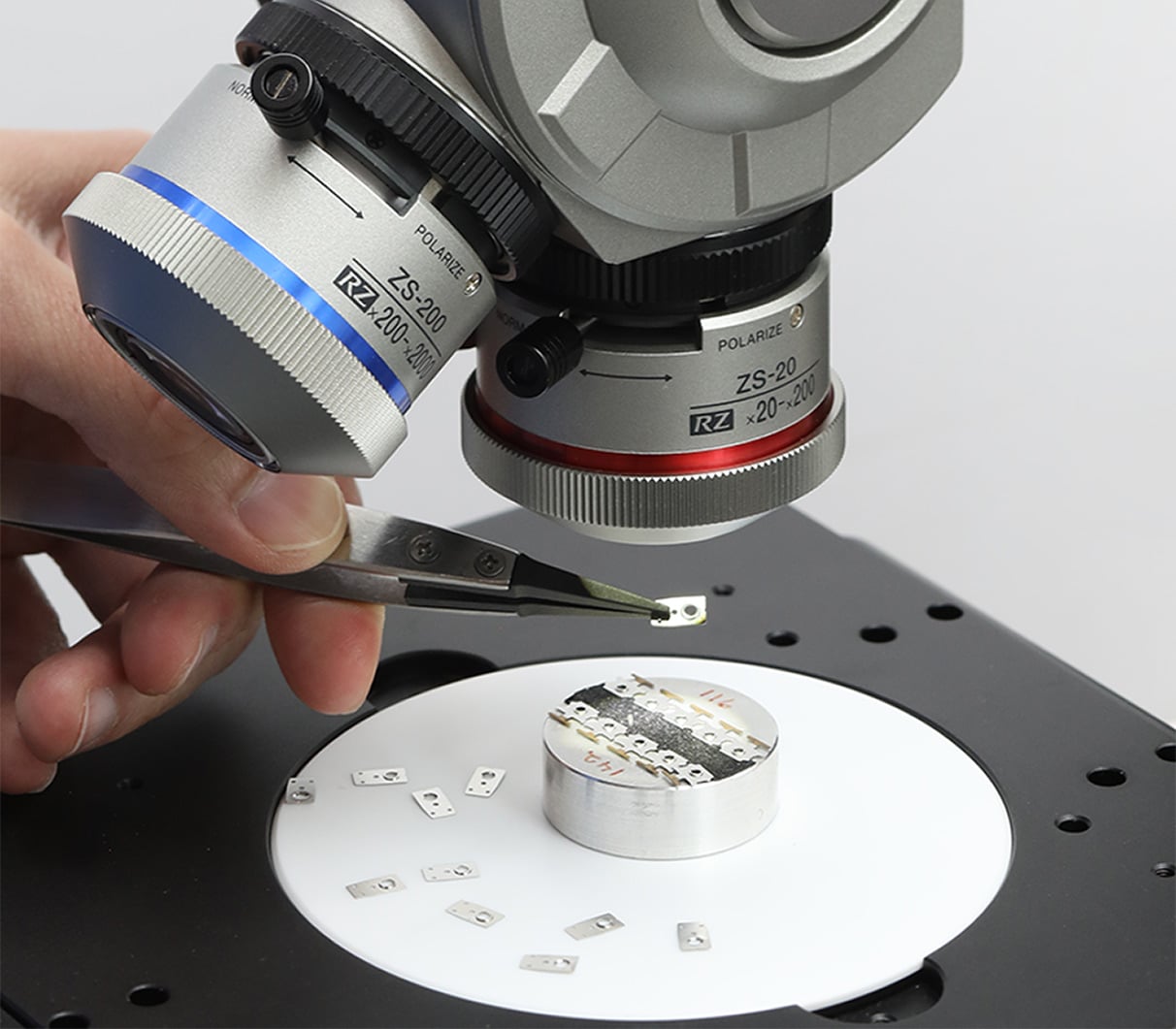

At IntriPlex’s Innovation Center, we can bring your product design to life in a matter of weeks. We use in-house state-of-the-art analytical tools such as Finite Element Analysis, Mechanical Resonance Testers, and a Scanning Electron Microscope with EDS to create and evaluate full-size metal prototypes. Our efficient process saves you time and money during product testing and validation, enabling speed to market.

delivery & Validation high performance is an intriplex cornerstone

Before products can be manufactured, they need to be thoroughly tested to guarantee their performance in use. This step is crucial to the design, manufacture and delivery of our products. Our testing capabilities mimic customer use to improve component performance and are known worldwide for their dependability and accuracy. We use dedicated engineers to research and we invest in methods and equipment to test customer requirements in-house. This expedites component and manufacturing innovations for our customers.

Wherever you are,

whatever the challenge

partner with us

The Innovation Center expedites development and collaboration, for quicker time to market and ramp to production. We are always on the look-out for new ways to develop metal stamping innovations that will help us better serve our customers. Tap into our world-class engineering and project management expertise, which spans everything from metallurgy, mechanical engineering, electrical engineering, chemical engineering, manufacturing technology, contamination control, particle dynamics and beyond.