THE MOST IMPORTANT

THING WE BUILD IS TRUST

EXPERTISE DEDICATED TO YOU

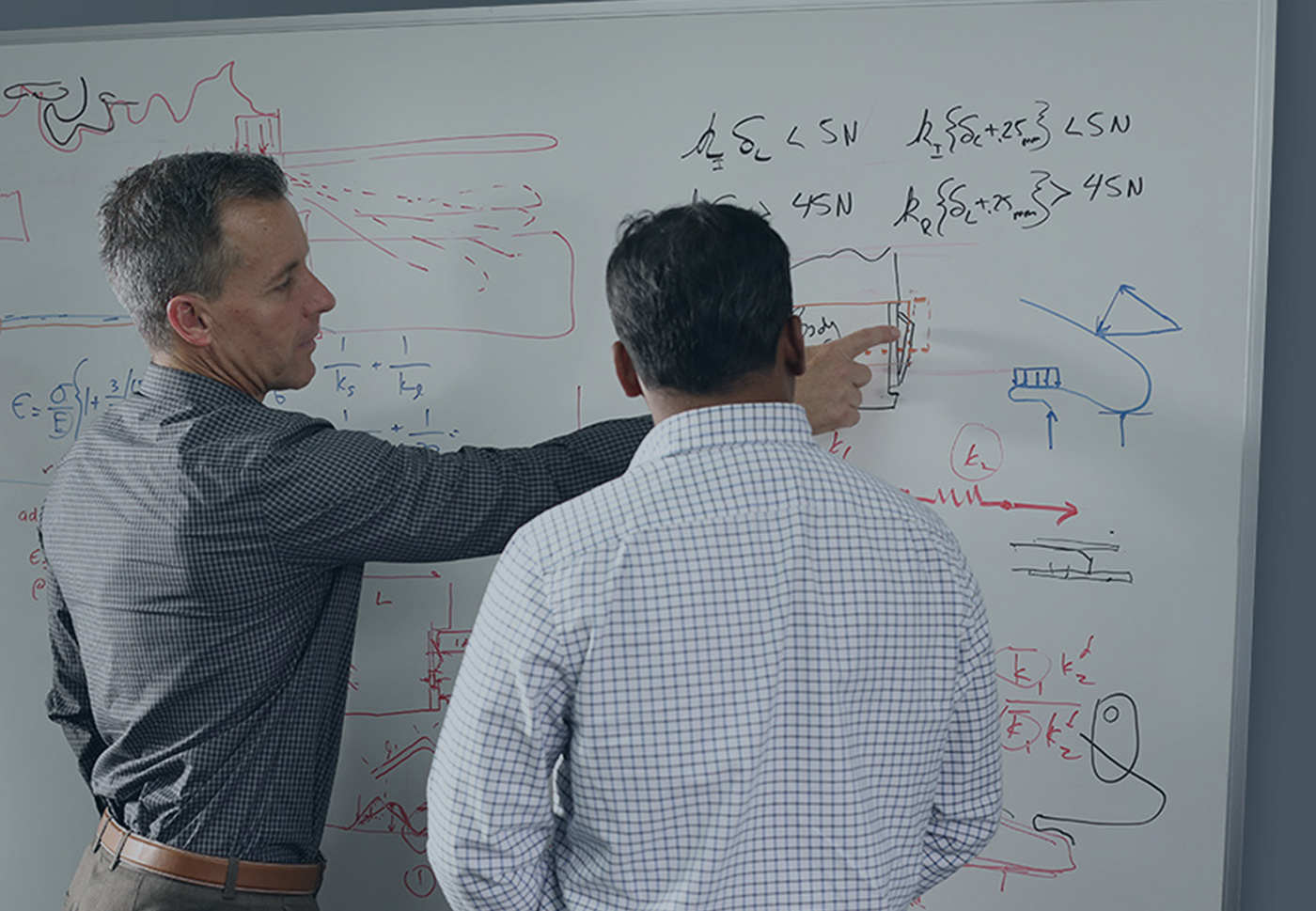

Our customer support process is simple, really. We want our customers to feel like we’ve anticipated their every need and over-delivered on every expectation. This isn’t just about our commitment to quality products and the highest level of customer service; it’s about the honesty of a handshake and the pride of giving our word. It’s about doing business with integrity and it’s about customers feeling taken care of. That’s our promise.

We have developed a base of customers that have been our partners for many years. Together we work closely to solve problems, break new ground, and accomplish things that have never been done before. In a spirit of collaboration, we work shoulder-to-shoulder with our customer teams. We establish trusting relationships that allow us to meet the challenges of the industry head-on.

CUSTOMER SUPPORT PROCESS

More insights, better decisions.

IntriPlex provides strategic manufacturing resources and full logistical support as products mature and move through their life cycle. With our customer support process, our customers work more effectively and achieve better results. Our goal is to use technology and services to support our customers in the best possible way. We automate processes, prepare data for analysis, and integrate systems, so our customers can concentrate on the really important things in their sales process.

-

- Step 1

Step 1

COMPONENT DESIGN & ANALYSIS

The nature of our component design and analysis approach is very project-specific, but the one key attribute common to all of our projects is our customer-focused approach. Whether performing a detailed analysis to determine the suitability of a certain design geometry or sitting with our customers to discuss conceptually their particular requirements for a new component, our commitment to getting our customers what they need is paramount.

-

- Step 2

Step 2

DESIGN FOR Manufacturability

Focusing on design optimization reduces the cost of manufacturing and is a critical step of the product development cycle. Design for manufacturing is where we merge the design requirements of the product with its production method, allowing us an opportunity to identify and prevent mistakes, often improving upon the design and the manufacturing process.

-

- Step 3

Step 3

Design for cost

We employ a systematic approach to controlling the costs of product development and manufacturing so that we provide value to all links of the manufacturing chain. We pay special attention to our customer’s target costing and all manners of project scope, staffing, scheduling, and coordination so that the final product is executed within their costing parameters. We look for opportunities to optimize the product design for cost efficiency, and we manufacture using the most efficient processes.

-

- Step 4

Step 4

QUOTING

We know that two of your biggest questions are “How much is it?” and “When can I get it?” Utilizing the tooling and automation expertise of our US-based engineering team and the cost-effective resources of our Thailand operations, IntriPlex provides a complete manufacturing solution at every stage of the product life cycle. We define the product architecture in the absence of physical parts so we can deliver thorough quotes that you can depend on.

-

- Step 5

Step 5

PROTOTYPING

Prototyping is the proof point of our innovative manufacturing solutions. Drawing upon our extensive experience and database of manufactured components from the last 35+ years, IntriPlex can deliver prototype solutions for real-world product testing and confirmation in 3-4 weeks. In most cases, prototypes are built using production-ready tooling, which means they can be qualified and are ready for ramp.

-

- Step 6

Step 6

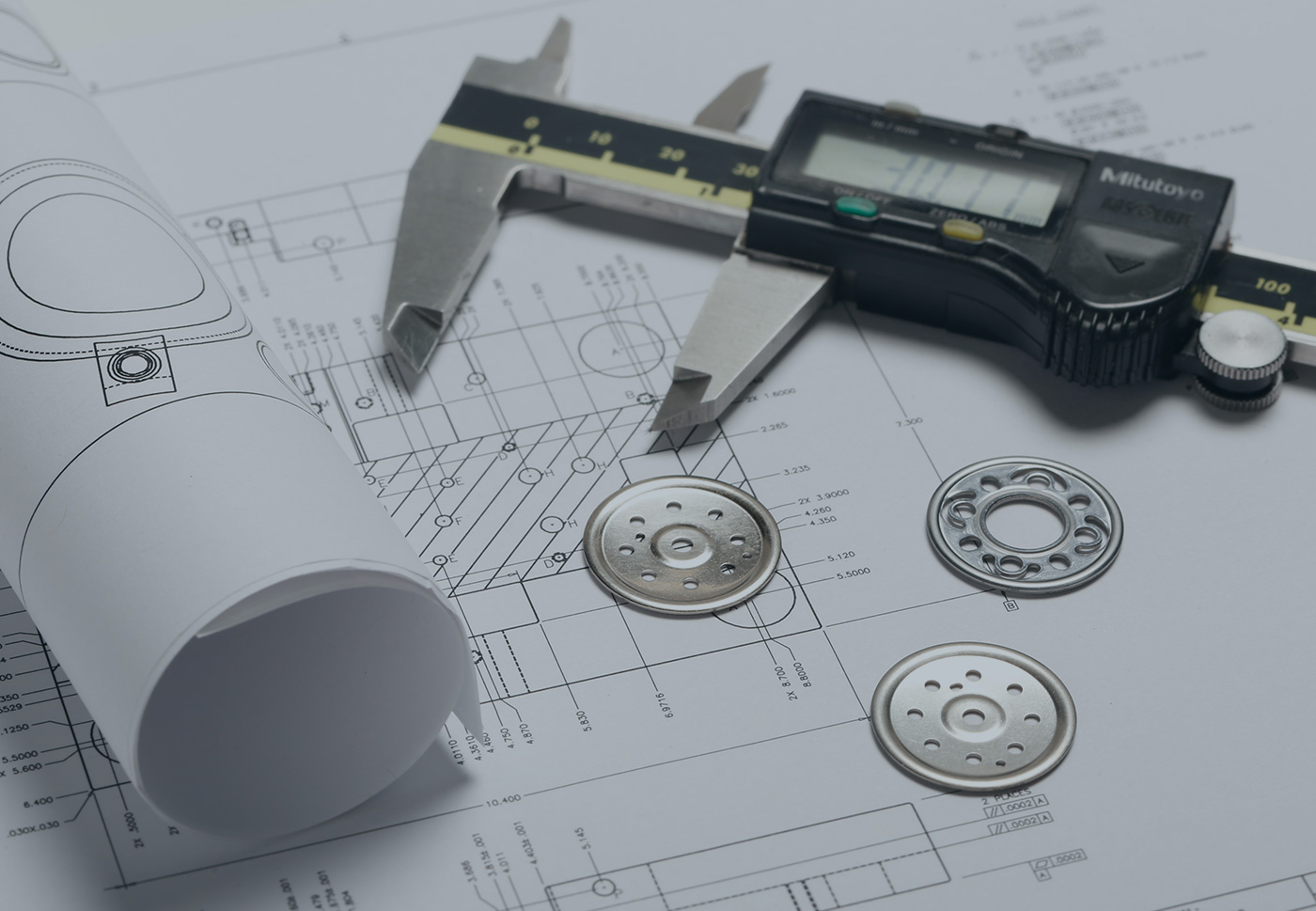

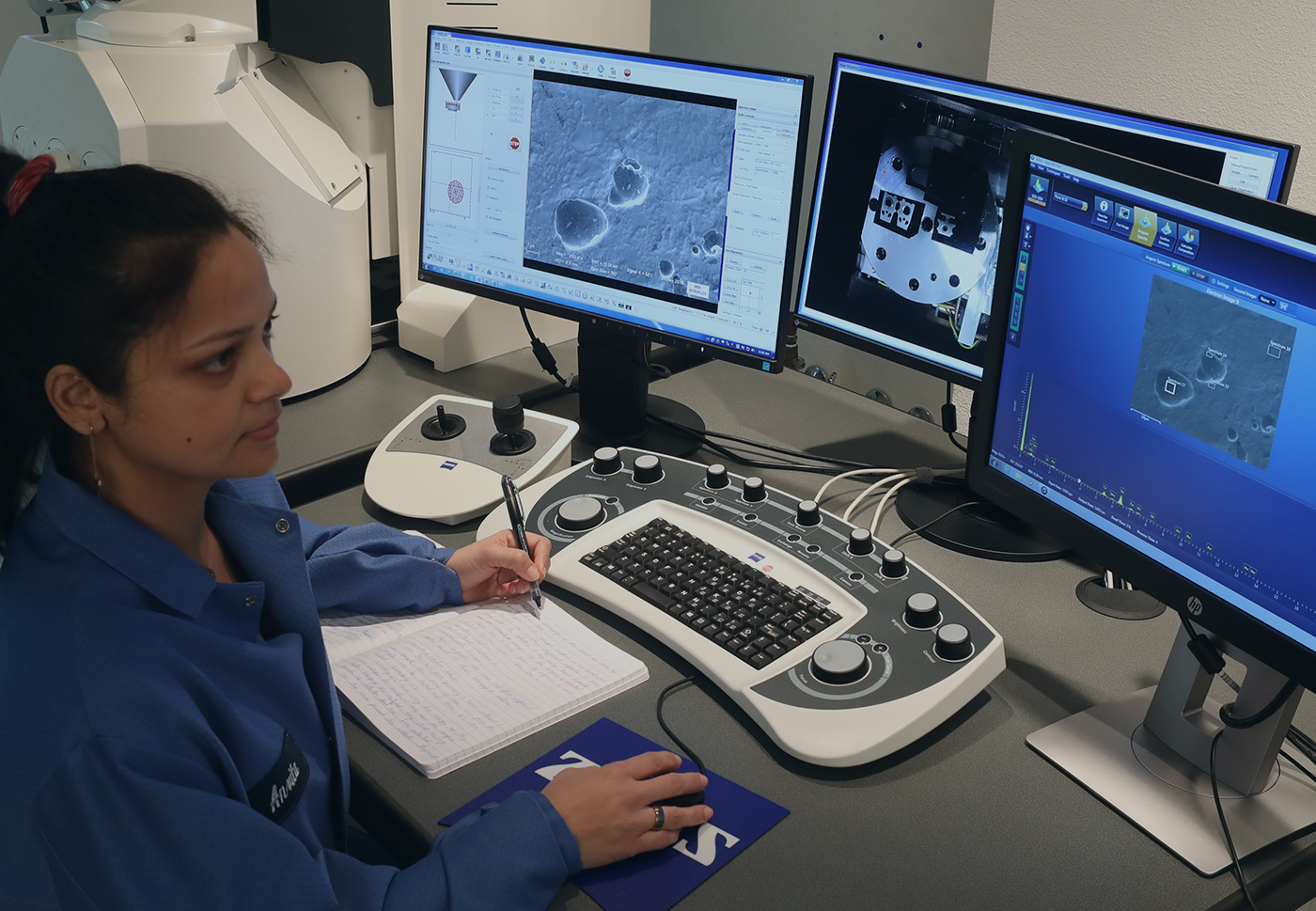

TESTING & MEASUREMENT

We measure what is needed to ensure success for our customers, well beyond print specifications. IntriPlex utilizes advanced metrology, testing protocols, and state-of-the-art tools to improve downstream product performance. Our labs are equipped to assemble and test our products as our customers would, ensuring we understand how our parts work in application.

-

- Step 7

Step 7

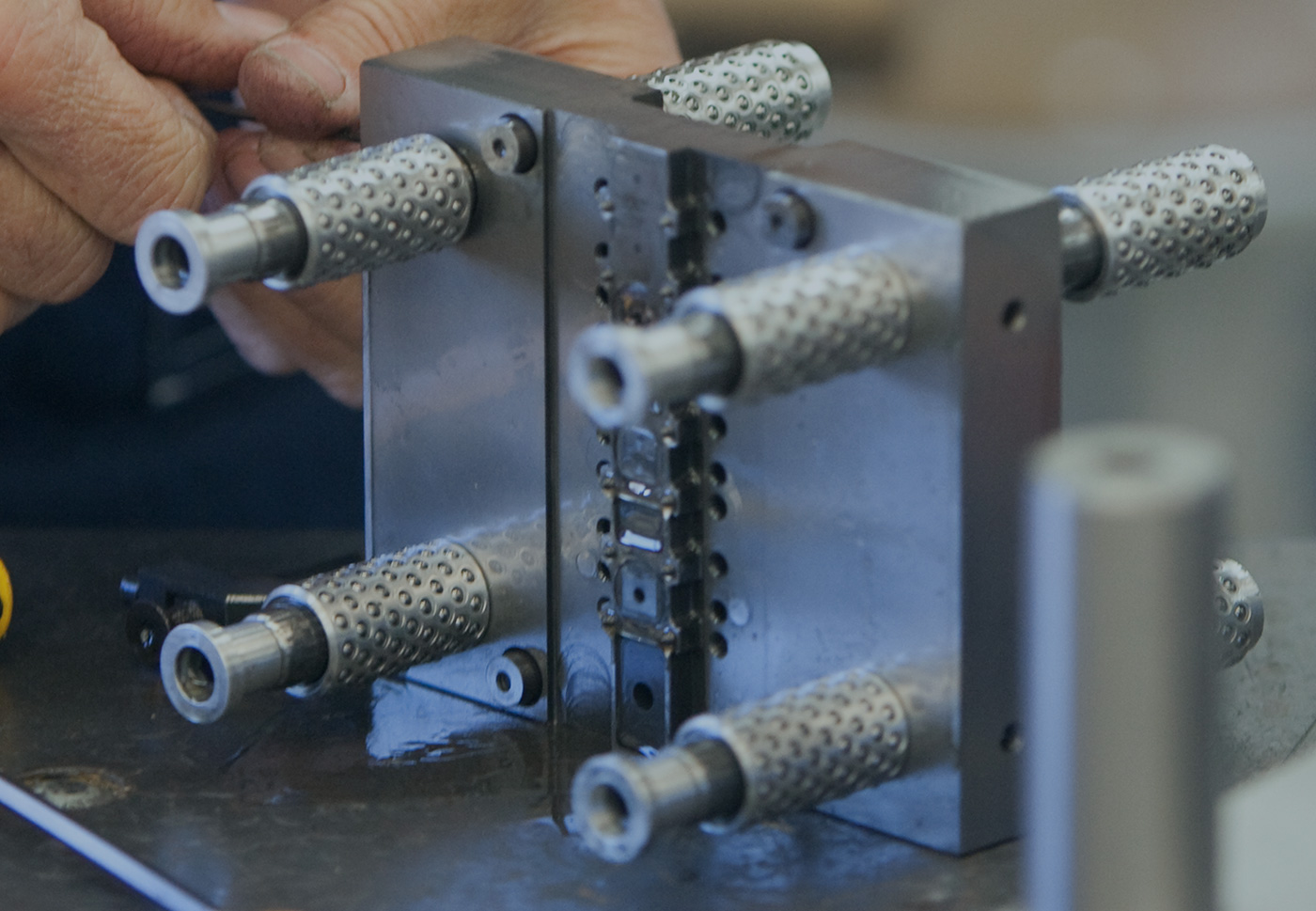

HIGH VOLUME MANUFACTURING

Once we have ensured we have the perfect spec adherence to meet your needs, we are capable of rapidly manufacturing your product and delivering it on time. Our highly automated progressive precision forming process is best suited for high-volume manufacturing.

5 BENEFITS OF OUR CUSTOMER SUPPORT PROCESS

01ACCURATE ASSESSMENT OF CAPABILITY AND QUALITY PARAMETERS

02SPECIFICATION REFINEMENT FOR MANUFACTURABILITY AND COST

03PRODUCT RELIABILITY

04REDUCED TIME-TO-MARKET

05INCREASED CUSTOMER SATISFACTION

CONFORMANCE AND REPEATABILITY ARE KEY

Our precision forming processes utilizes rigorous manufacturing discipline and statistical process control with automated alerts, ensuring that our customers get consistently high-quality product every time.