WE BELIEVE IN THE

POWER OF ‘WHAT IF?’

WE ARE LEADERS IN PRECISION FORMING

We are curious about the future and so we always look further. We lead a streamlined, effective process, backed by 30+ years of continual and diligent research, engineering know-how, innovative technology, and agile procedures. With a track record of firsts, we consistently deliver world-class products and services—reinventing the metal stamping industry with advanced precision forming technology, thinking big, and acting bigger.

BUT FIRST, A QUICK INTRODUCTION TO PRECISION METAL STAMPING

WHAT IS

PRECISION METAL STAMPING?

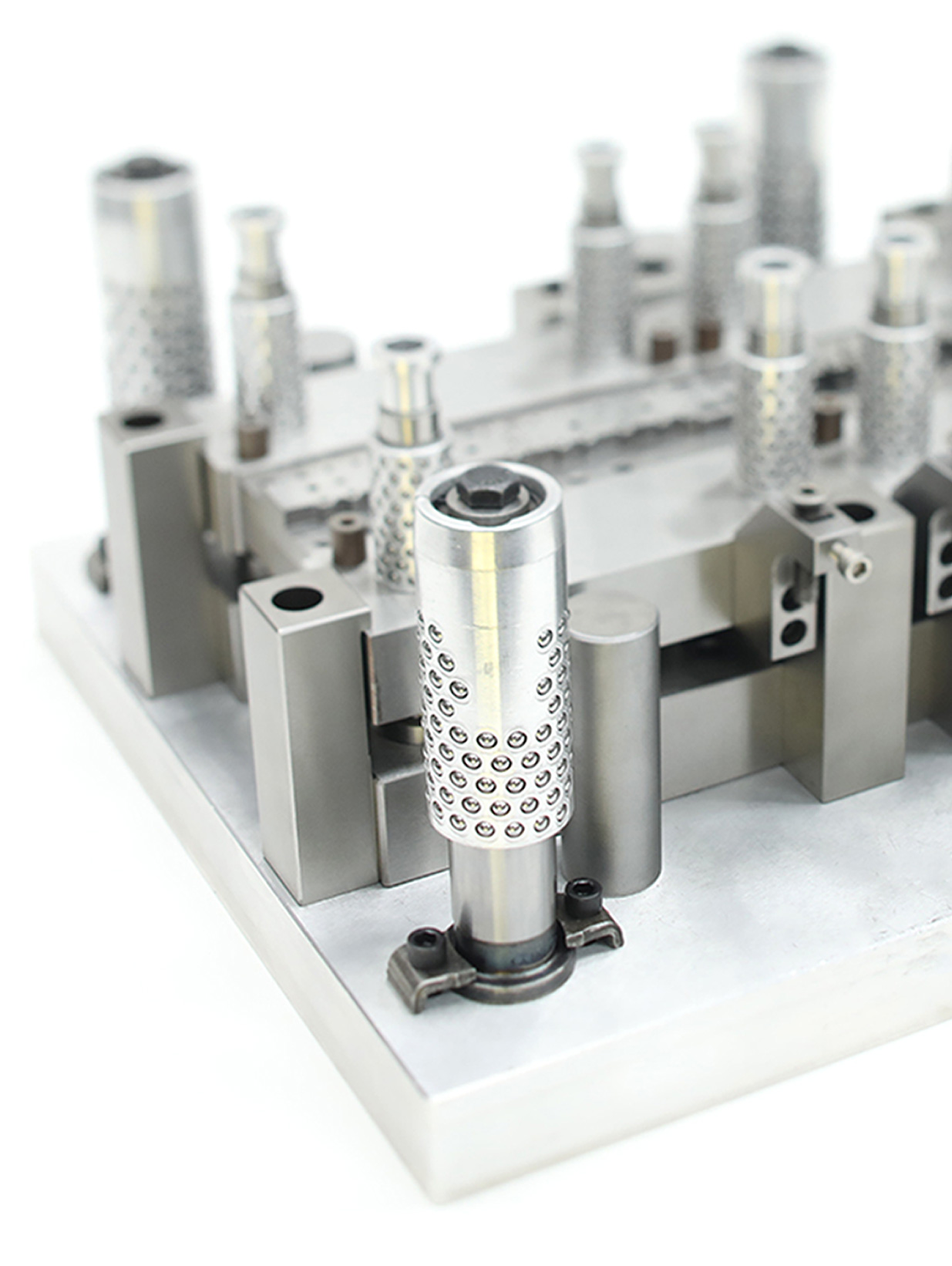

Metal stamping is a manufacturing process that uses presses and custom progressive dies to create parts with distinct shapes. A strip of metal is fed into the die set assembly mounted in the press. The strip is advanced progressively through multiple die stations between each vertical stroke of the press ram where precision-fabricated tooling performs different operations on the part blank. Components with exacting accuracy and consistency are output from the last die station.

THE INTRIPLEX DIFFERENCE

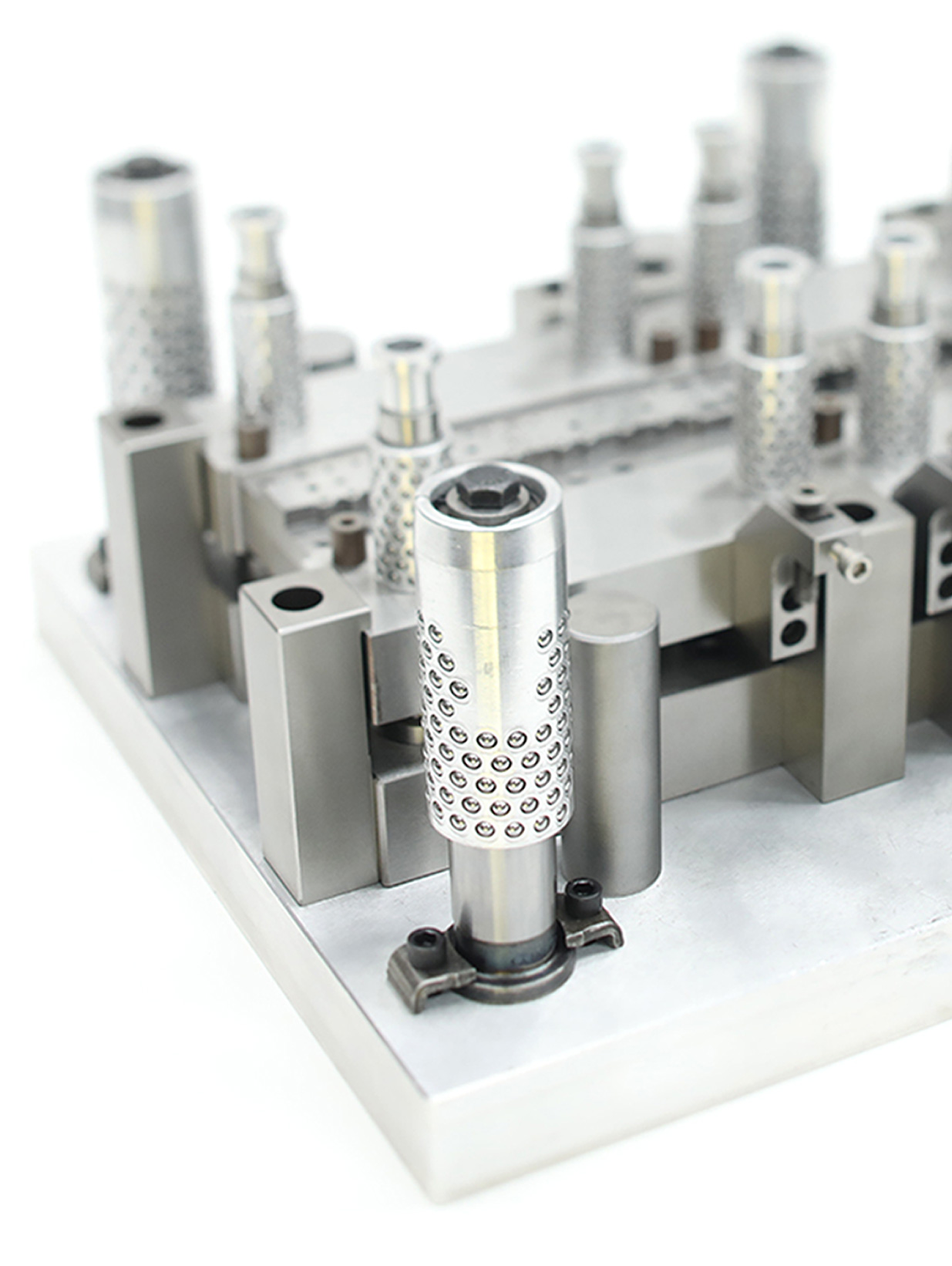

We’ve built our reputation on exploring new perspectives and successfully pushing the boundaries of what is possible by stamping what has previously been considered “unstampable.” Most metal stamping companies utilize various operations of cutting, bending, and punching to create desired shapes, but IntriPlex excels at the most complicated function of stamping: forming. Our metal forming technologies enable the creation of products with thick sections and intricate inside and outside diameter features by flowing and filling material from the thin flat material strip that is fed into the die.

Our process generates small, highly detailed parts with extreme fidelity, and we deftly handle part specifications with the most impressive tolerances. Our ability to achieve complex and complete parts through a single metal stamping operation eliminates the need for costly secondary operations, saving our customers time and money.

At IntriPlex, we take the long view, solving our customer’s important challenges through the convergence of breakthrough science, engineering, and leadership. Our world-class progressive stamping infrastructure combined with advanced in-house die designs, materials expertise, and extremely tight quality control enables the manufacture of complete and complex components that are unachievable using traditional stamping processes.

THE INTRIPLEX DIFFERENCE

We’ve built our reputation on exploring new perspectives and successfully pushing the boundaries of what is possible by stamping what has previously been considered “unstampable.” Most metal stamping companies utilize various operations of cutting, bending, and punching to create desired shapes, but IntriPlex excels at the most complicated function of stamping: forming. Our metal forming technologies enable the creation of products with thick sections and intricate inside and outside diameter features by flowing and filling material from the thin flat material strip that is fed into the die.

Our process generates small, highly detailed parts with extreme fidelity, and we deftly handle part specifications with the most impressive tolerances. Our ability to achieve complex and complete parts through a single metal stamping operation eliminates the need for costly secondary operations, saving our customers time and money.

At IntriPlex, we take the long view, solving our customer’s important challenges through the convergence of breakthrough science, engineering, and leadership. Our world-class progressive stamping infrastructure combined with advanced in-house die designs, materials expertise, and extremely tight quality control enables the manufacture of complete and complex components that are unachievable using traditional stamping processes.

WHY YOU SHOULD STAMP WHENEVER POSSIBLE

There is no metal part fabrication process faster than stamping. Complicated part geometries can be produced upwards of 1,000 per minute, and simple geometries can be made even faster. You can expect a quicker turnaround time to reduce your production ramp lead times.

The inherent benefit of stamping is its low part-to-part variability. For features such as flatness and concentricity, our dimensional control exceeds traditional manufacturing capability enabling strict Cpk adherence. The repeatability of our precision forming process also ensures low “within-lot” and “lot-to-lot” variability.

Stamping easily scales with tooling. Assuming a factory has adequate press availability, replication of the stamping die can easily increase stamping capacity. Also, multiple jobs can be interchanged quickly within a single press, allowing for scheduling flexibility. Current IntriPlex capacity exceeds 146 M parts/month.

With the increased efficiency of stamping vs. machining, the savings allow for lower operating costs up to 50%. IntriPlex passes those cost savings onto our customers to help make them the most competitive in their market, truly a win-win!

We Bring Solutions

What can be achieved when science, intellectual curiosity, and years of extensive manufacturing experience and process technology come together? At IntriPlex, every challenge is treated as an opportunity. We deploy advanced engineering and science, metrology, precision cleaning, and automation to design, develop, and produce products and solutions tailored to specific applications.

We have worked on many successful projects that have made a real impact on our customers’ businesses. Every day we come to work to push boundaries and change how the world uses precision-forming technology.

We take pride in the work we do. Any stamping company can reinvent or create products, but few can say that they offer the chance to make history and help our customers transform their industry.

-

- Learn how

LEARN HOW OUR SOLUTIONS ARE REVOLUTIONIZING INDUSTRIES

-

- Automotive

Automotive

We were the first company to develop a precision forming process for fuel injector nozzles with high material thickness to hole diameter aspect ratios and axially-oriented nozzle holes, enabling breakthroughs in direct injection technology.

-

- DATA STORAGE

DATA STORAGE

In the data storage industry, we were the first company using precision forming technology to offer features to offset the loss of stiffness from required disk clamp holes, for more uniform clamp force and improved HDD performance. IntriPlex disk clamps also offer features to capture particles generated during HDD assembly for improved drive reliability.

-

- FIBER OPTICS

FIBER OPTICS

The fiber optic connector market requires geometrically complex components at high volume and low cost. IntriPlex was the first (and remains the only) company in the world that can stamp select aluminum components utilized inside the connectors. Displacing the traditionally machined parts allows for significant cost savings.

-

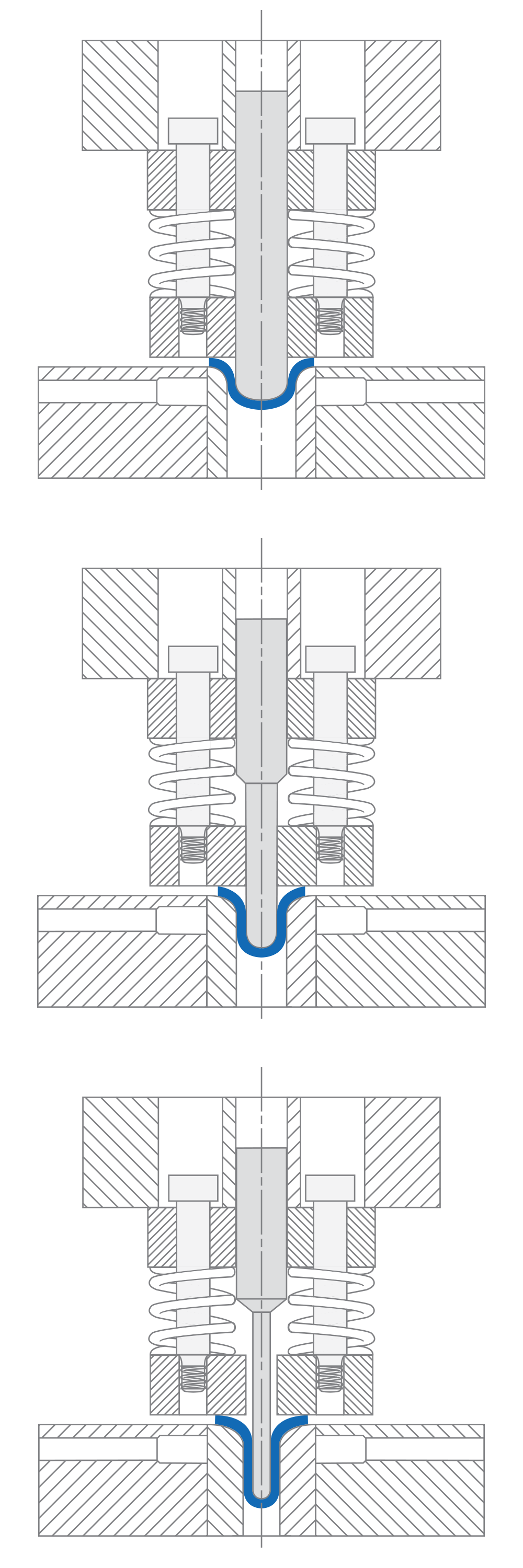

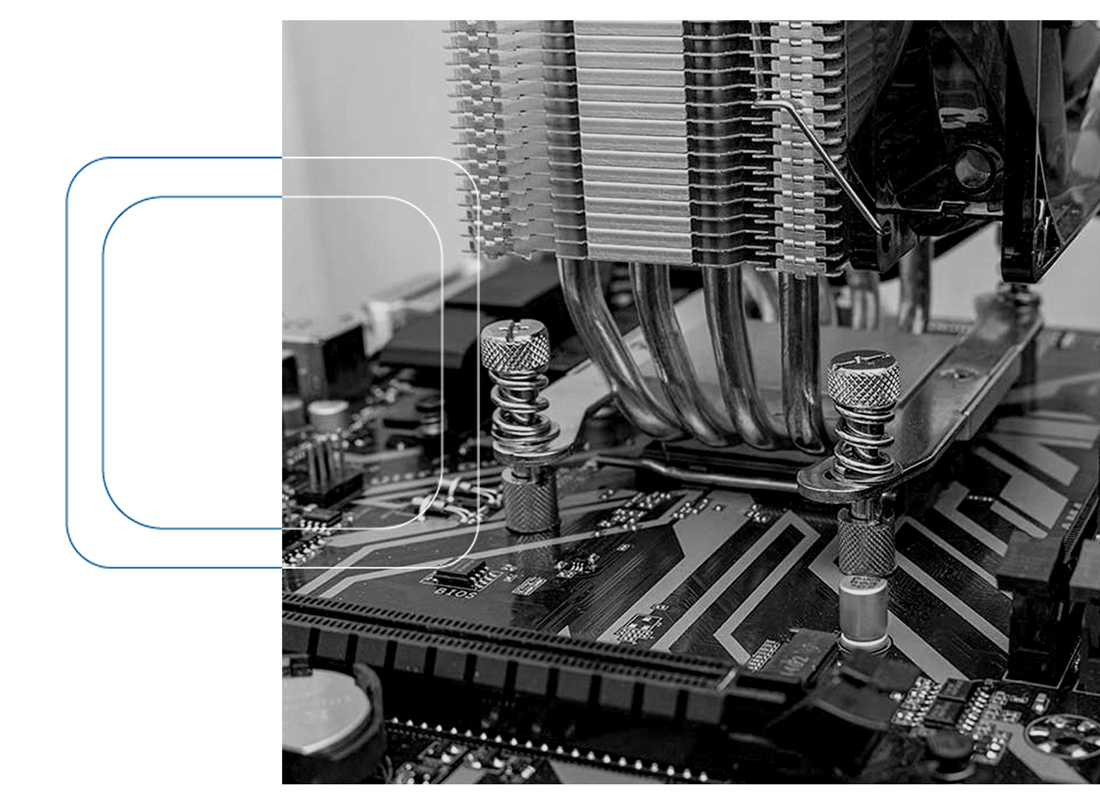

- MICROPROCESSOR

MICROPROCESSOR

In the microprocessor industry, we were the first company to develop a process to fully create integrated heat spreaders using precision forming technology without the use of secondary operations, resulting in lower cost and more repeatable components. 100% of heat spreaders used today are made by this method.

-

- MEDICAL

MEDICAL

IntriPlex’s (and later IntriMed’s) dedication to innovation resulted in the creation of the world’s first stamped medical needle for Medtronic. The need for a mass-produced design with critical patient-comfort attributes resulted in the IntriPlex stamped needle for diabetes treatment.

Did you know

NOT ALL METAL STAMPing companies are created equal

Our high-speed stamping process builds parts 25x faster than the highest speed Swiss Screw Machine. That’s what we call efficiency!

We push the limits on more than just product dimensions, our most strict product cleanliness metrics routinely measure for particle contamination down to 0.200 microns. That’s 50x smaller than the finest particle of pollen.

For key features, we can hold dimensional tolerances down to ±3 microns—or more than 15 times smaller than the diameter of a human hair.

We utilize Statistical Process Control methods to ensure strict 0.15% AQL for dimensional and visual adherence of more than 2.5 Million parts shipped per day.

The

IntriPlex

Way

A model defined by technical leadership and rooted in a commitment to unparalleled service.

Collaboration

Our customers have the requirements and applications. We welcome you in to work side by side in developing tailor-made solutions.

Eminent accuracy

Our customers have the requirements and applications. We welcome you in to work side by side in developing tailor-made solutions.

Always Achieving

IntriPlex’s ability to stamp parts that no other manufacturer can manage is a major boon to your customers. The only thing we love more than an audacious whiteboard sketch is an audacious design stamped.