Engineering components for

the future of energy and data

welcome to intriplex

At IntriPlex Technologies, we’re more than manufacturers—we’re precision engineers enabling the systems that power and connect the modern world. Specializing in high-volume metal stamping and forming technology, we’re recognized worldwide for our engineering excellence, unmatched product quality, and a diverse innovation portfolio spanning numerous industries.

Across every industry we serve, our teams advance manufacturing capability through precision engineering and innovation. From pioneering battery assembly capabilities to supporting next-generation digital infrastructure, we apply the same technical rigor, scale, and reliability wherever performance and consistency matter most.

Headquartered in Santa Barbara, California, with manufacturing operations in the USA and Thailand, we serve not just as a partner, but as a catalyst for progress.

MORE THAN

experience

We’re a well-seasoned and trusted provider of high-precision stamped metal components and assemblies for the world’s most technically demanding applications.

MORE THAN

parts produced

Our high-speed precision metal stamping technology delivers high volume and superior quality, ensuring reliable supply and capacity for leading global manufacturers.

MORE THAN

patents granted

We are a technology partner; our commitment to research and development has led to significant advancements in custom metal stamping technology, fueling a competitive advantage for our customers.

In the spotlight

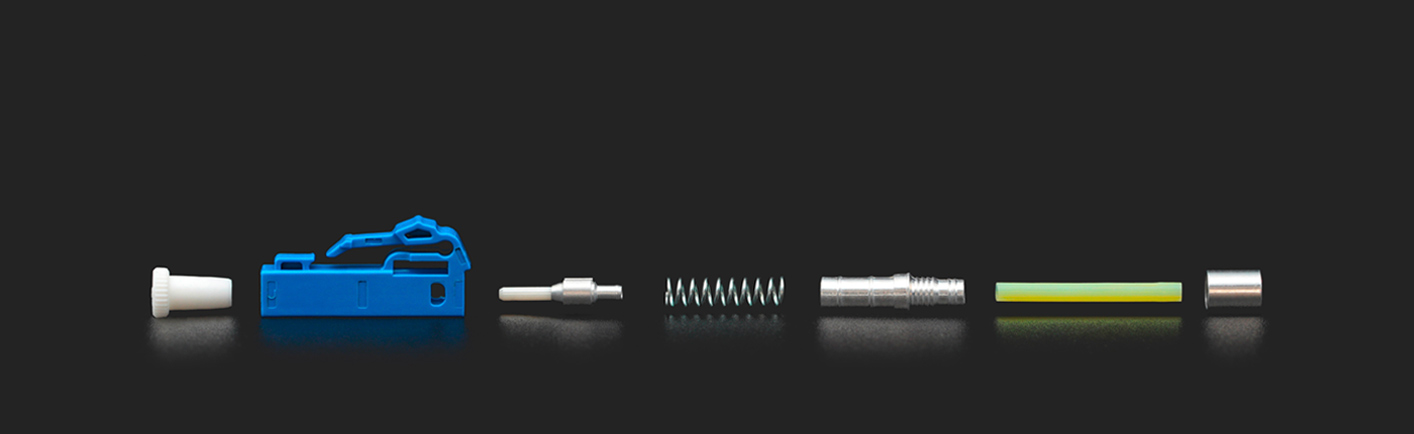

ADVANCING FIBER OPTIC TECHNOLOGY

FOR HIGH-DENSITY CONNECTIVITY

Growing network demands, from hyperscale data centers and enterprise infrastructure to telecom and broadband networks, call for fiber optic solutions engineered for precision and scalability. Our advanced stamping capabilities deliver uniquely complex, high-performance components—from rings and clips to rear bodies—with repeatable quality and cost-efficient production, supporting the evolving connectivity landscape.

BETTER BATTERY PARTS,

COMPLETE ASSEMBLIES

Across EVs, energy storage, and industrial systems, lithium-ion batteries rely on components with exacting tolerances, reliability, and manufacturability at scale. IntriPlex’s core stamping and forming technologies transform complex structural components and lid assemblies into high-performance, cost-efficient solutions, enhancing structural integrity and thermal performance in every battery pack.

An IntriPlex Partnership

Offers Unparalleled Advantages

We work alongside industry leaders across energy storage, fiber optic, medical, and other technically challenging markets, delivering custom precision-stamped solutions that enhance product quality, reliability, and scalability.

Our decades-long focus on precision metal stamping, combined with deep engineering expertise and advanced manufacturing capability, allows us to disrupt conventional approaches and introduce stamped components where machining was once considered the only option.

Trusted by leading global OEMs, we continue to set the standard for precision, performance, and innovation across next-generation technologies.

A STRATEGIC ALLY WITH UNMATCHED CAPABILITIES

We deliver tailor-made solutions and services that integrate seamlessly with your operations—minimizing risk, solving complex challenges, and executing mission-critical stamped components where, when, and how you need them.

INTRIPLEX PRECISION METAL STAMPING SOLUTIONS

POWERING ENERGY STORAGE AND HYPERSCALE INFRASTRUCTURE

We focus on the development of core technologies in precision metal stamping to create new value across the world’s most demanding applications. Built on integrity and committed to value, our approach is simple: we treat our customers’ needs, performance goals, and budgets as if they were our own. We believe long-term collaboration is built through trust, technical excellence, and consistently exceeding expectations.